Best Industrial Infrared Heating and Drying System: IR System

SAVE MINIMUM 20% on RUBBER GLOVE Oven’s GAS ENERGY COST

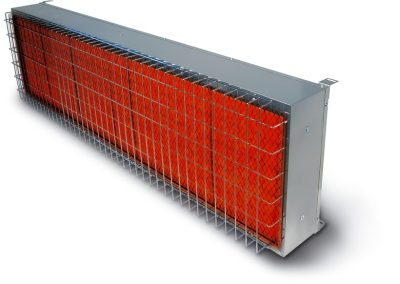

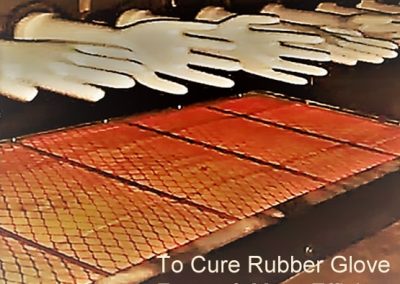

IR CATALYTIC SYSTEM, can CURE your RUBBER GLOVE FASTER and MORE EFFICIENT because;

- Natural Peak Absorbance wavelength for organic substances ~ water, epoxy, polyester, ABS and acrylic is 2 – 4 microns.

- Although infrared is used alone as an effective heating technique, there are many processes where it can be used more effectively in combination with other heating techniques, particularly convection (hot air).

- If the process requires the removal of water, the introduction of an air stream is important to remove the evaporated water.

- Combined electromagnetic radiation and hot air heating is considered to be more efficient

- Localise heating, use when and where is needed, increase line speed and output capacity.

- No flame oven system.

- Big gas energy saving (10%-20%), save money and save the world with a lower carbon footprint.

Learn more about How Our IR Catalytic System can help your factory achieve more production with lower cost & energy!

What Industries can be used for

Infrared Drying system

Metal & Aluminium

Automotive

Manufacturing

Glove & Condom

Frequently Asked Questions Regarding Industrial Infrared Heating System

What is an industrial infrared heating or drying system?

Industrial infrared heating and drying systems are one of the drying methods that leverage electromagnetic radiation to heat target materials directly at a molecular level. It contrasts with conventional convection methods that heat the surrounding air. The targeted nature of infrared heating translates to efficient drying of paints, coatings, inks, and moisture removal across various products. These systems are prized in industrial settings for their rapid processing times, precise temperature control, and lower energy consumption than traditional convection ovens.

How do the infrared heating systems work?

An infrared heating system converts electrical energy to thermal energy, which is infrared (IR) radiation, an invisible type of heat transfer. These waves travel directly to objects in their path, heating them without warming them. Imagine sunshine directly warming you instead of heating the air around you. The heated objects then radiate heat back into the surrounding air, creating a more comfortable and efficient heating experience.

What are the benefits of an infrared drying system?

Infrared drying systems offer several advantages over traditional methods:

- Faster Drying Times: Infrared radiation heats directly at the molecular level, leading to significantly quicker drying times than convection ovens that heat the air first. This translates to increased production efficiency and throughput.

- Improved Product Quality: Rapid and targeted heating can minimise heat damage to materials, preserving their quality and characteristics. This is especially beneficial for temperature-sensitive products like food or pharmaceuticals.

- Energy Efficiency: Infrared systems heat directly, reducing wasted energy to warm the surrounding air. It can lead to substantial energy cost savings compared to conventional dryers.

- Compact Design: Infrared dryers often require less physical space due to their targeted heating approach. It can be a significant benefit in facilities with limited space.

- Precise Control: The ability to precisely control the intensity and wavelength of infrared radiation allows for fine-tuned drying processes, ensuring consistent results.

- Versatility: Infrared drying systems can be adapted for various applications and materials, making them versatile tools across multiple industries.

What are the applications of an industrial infrared dryer?

IR dryers find numerous applications across various processes, particularly excelling in drying, curing, and forming tasks. Here are some key areas where they shine:

- Drying: Infrared’s ability to directly heat materials makes it ideal for drying applications. This includes paint, coatings, inks, and adhesives on various products, from car parts to furniture to textiles.

- Curing: Infrared heat cures various materials like plastics, composites, and food products. The precise control allows uniform heating without damaging the material on a conveyor belt.

- Plastic Forming: Thermoforming and vacuum forming techniques rely on infrared’s targeted heating to efficiently soften and shape thermoplastics into desired forms.

- Adhesive Activation: Many adhesives require heat to activate their bonding properties. Infrared heaters provide a clean and efficient way to achieve this in industrial processes without direct contact.

- Glass Manufacturing: Infrared plays a crucial role in glass processing, including laminating multiple glass layers, bending glass for shaping, and annealing to relieve stress in the material.

- Textile Production: Infrared heaters are used to dry textiles after dyeing or washing and to set dyes and wrinkles.

- Spot Heating: Infrared’s targeted nature makes it ideal for heating specific areas or objects within a larger workspace, improving efficiency and reducing energy waste.

What is the temperature of industrial infrared heaters?

Discover the Power of Our Industrial Infrared Heating and Drying System

Our system offers precise temperature control and reduces energy consumption by up to 20%, making it efficient and cost-effective. Contact Isses today to learn how our system can revolutionise your manufacturing processes.

Email us

CHAT with us

Whatsapp our sales team to ask more!

We will get back to you as soon as possible.

CONTACT

INFORMATION

Industrial System Supply & Engineering Services Sdn Bhd

No.7, Jalan Melati 2, Seksyen BB 11 Bukit Beruntung, 48300 Rawang, Selangor Darul Ehsan, Malaysia.

Tel. +603 6028 4188

sysam@isses-tech.com

frontdesk@isses-tech.com

CONNECT WITH US