As industries across Malaysia continue to evolve toward greener, smarter, and more cost-efficient operations, energy consumption has become a critical area of concern. Industrial processes that involve heating are among the most energy-intensive. That’s where the High-Efficient Heating Chamber comes in — a technological advancement designed to revolutionise how industries handle thermal processing.

From manufacturing and electronics to food processing and pharmaceuticals, a high-efficient heating chamber ensures precise temperature control, reduced energy consumption, and improved output quality. In this comprehensive guide, we will explore what makes these heating chambers superior, why they’re crucial for industrial transformation in Malaysia, and how ISSES Malaysia is leading the change with innovative thermal solutions.

What Is a High-Efficient Heating Chamber?

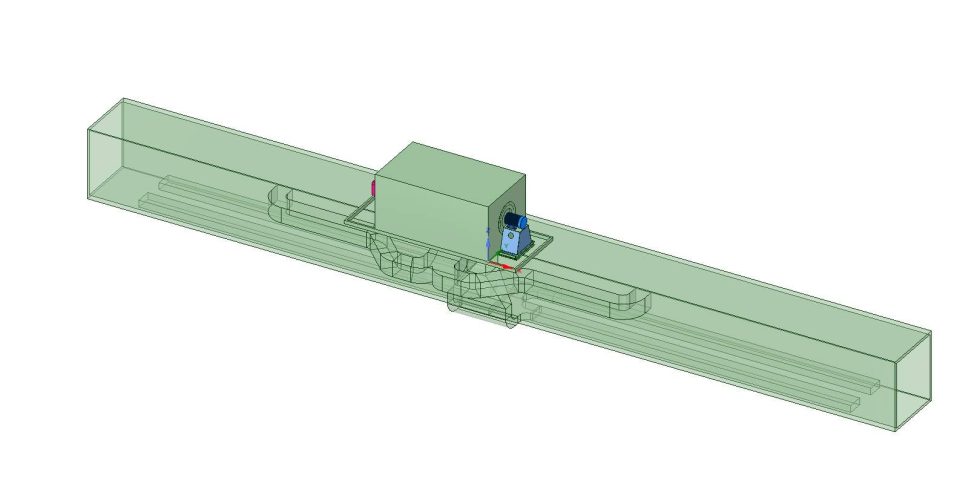

A high-efficient heating chamber is an advanced thermal system engineered to deliver maximum heat output with minimal energy input. It utilises intelligent airflow, high-grade insulation, digital control systems, and heat recovery technologies to provide efficient and uniform heating.

These chambers are used in a wide variety of applications, including:

- Metal treatment and hardening

- Plastic component curing

- Electronics drying and testing

- Food sterilisation and dehydration

- Pharmaceutical product processing

- Laboratory research and quality control

In essence, high-efficient heating chambers are the next generation of industrial ovens and kilns, built not just for performance but for sustainability and energy optimisation.

Key Features of a High-Efficient Heating Chamber

To understand what sets a high-efficient heating chamber apart from traditional systems, let’s examine the features that drive its performance:

1. High Thermal Efficiency

The core benefit is reduced energy consumption. These chambers use efficient heating elements and high-performance insulation materials to limit heat loss. Efficiency levels can exceed 90%, especially in models with integrated heat recovery.

2. Uniform Temperature Distribution

Advanced airflow systems and intelligent design ensure that heat is distributed evenly across all zones of the chamber, eliminating cold spots and ensuring consistent processing.

3. Digital and IoT Control Systems

Modern heating chambers come equipped with programmable logic controllers (PLCs), touch-screen interfaces, and IoT connectivity for remote monitoring, data logging, and predictive maintenance.

4. Rapid Heating and Cooling Cycles

High-efficient chambers are capable of faster ramp-up and cooldown rates, reducing cycle times and increasing throughput.

5. Low Emissions and Environmental Impact

Reduced fuel or electricity usage translates to a smaller carbon footprint — an important consideration for companies aiming to comply with ISO 14001 and other environmental regulations.

6. Smart Safety Features

Overheat protection, emergency shut-offs, and automatic diagnostics are standard, ensuring safe operation even under demanding conditions.

Why Efficiency Matters: Energy Costs in Malaysian Industry

Energy costs continue to rise in Malaysia, particularly in the commercial and industrial sectors. For factories and plants that rely heavily on thermal processes, inefficient heating systems can account for up to 40% of total energy usage.

Let’s break down why high-efficient heating chambers are crucial for Malaysian businesses:

● Cost Savings

By improving energy efficiency, businesses can cut down on their Tenaga Nasional Berhad (TNB) electricity bills by thousands of ringgit annually. Even a 15% improvement in thermal efficiency can result in massive savings over time.

● Sustainability Commitments

Malaysia’s National Energy Transition Roadmap (NETR) and Green Technology Master Plan 2030 emphasise energy-efficient technologies. A high-efficient heating chamber aligns with these initiatives, helping businesses earn green certifications.

● Competitive Advantage

Energy-efficient operations improve profitability and ESG scores, increasing a company’s appeal to investors, partners, and overseas clients, especially in eco-conscious markets like the EU and Japan.

Applications of High-Efficient Heating Chambers in Malaysia

These chambers can be adapted to a wide range of industries and applications:

1. Electronics and Semiconductor

Used in component drying, soldering, and thermal stress testing, where temperature uniformity and precision are critical to product performance.

2. Food and Beverage Processing

Ensures hygienic, uniform cooking or drying of food products while maintaining energy efficiency—crucial in sectors like halal food production.

3. Pharmaceutical Manufacturing

Maintains sterile conditions for drying, curing, or sterilising medical devices and drugs. Complies with Good Manufacturing Practice (GMP) and FDA standards.

4. Automotive and Aerospace

Used in heat treatment of metals, bonding of composite materials, and powder coating. High temperature accuracy improves durability and performance.

5. Research and Development Labs

Ideal for experiments requiring controlled thermal environments, whether for testing new materials or conducting quality assurance procedures.

Cost Comparison: Traditional vs. High-Efficient Heating Chambers

| Feature | Traditional Heating Chamber | High-Efficient Heating Chamber |

|---|---|---|

| Energy Consumption | High | Low (20–40% savings) |

| Heat Uniformity | Inconsistent | Highly uniform |

| Temperature Control | Manual or analog | Digital, programmable |

| Maintenance Frequency | High | Low |

| Operational Cost | Higher over time | Lower over time |

| Environmental Impact | High emissions | Low emissions |

| ROI | Long-term | Achievable in 1–3 years |

While traditional heating chambers may be cheaper upfront, the total cost of ownership for high-efficient models is significantly lower due to energy savings and longer equipment lifespan.

Choosing the Right High-Efficient Heating Chamber for Your Operation

Before investing in a high-efficient heating chamber, consider the following:

1. Temperature Range Requirements

Ensure the chamber can meet your peak heating needs, whether it’s 150°C for food drying or 1000°C for metal hardening.

2. Size and Load Capacity

Choose a chamber that fits your available space and production capacity, including batch or continuous operation modes.

3. Control and Automation

Look for models with PLCs, HMI displays, and IoT connectivity for smarter operation and integration with existing factory systems.

4. Energy Source

Electric or gas? High-efficient electric models are suitable for cleanrooms and labs, while gas-powered systems may be preferred for heavy industrial use.

5. Compliance

Make sure your heating chamber meets local and international standards such as MS, IEC, ISO, CE, and other relevant certifications.

6. Local Support and Maintenance

Choose a supplier like ISSES Malaysia that offers local service support, preventive maintenance packages, and fast parts availability.

ISSES Malaysia: Your Trusted Partner in High-Efficient Thermal Solutions

As a leading industrial solutions provider, ISSES Malaysia (Industrial System Supply & Engineering Services Sdn Bhd) offers state-of-the-art high-efficient heating chambers tailored to Malaysian businesses.

Our Services Include:

- Custom chamber design and engineering

- Installation, testing, and commissioning

- Energy audits and ROI consultation

- Preventive maintenance contracts

- Retrofit solutions for existing heating systems

Our systems are used in facilities across Selangor, Penang, Johor, and Sabah — helping businesses optimise operations and reduce energy waste.

Government Incentives and Energy Efficiency Grants in Malaysia

Businesses in Malaysia looking to upgrade to high-efficient heating chambers can take advantage of several government-backed initiatives:

● Green Investment Tax Allowance (GITA)

Provides tax incentives for companies investing in green technology equipment and systems.

● Green Technology Financing Scheme (GTFS)

Offers financing with government support for energy-efficient equipment and systems.

● Energy Audit Conditional Grant (EACG)

Supports the cost of conducting energy audits for manufacturing and commercial buildings.

● Sustainable Energy Development Authority (SEDA)

Promotes energy efficiency through regulatory and incentive mechanisms.

These incentives can significantly offset your capital investment and accelerate your ROI.

Case Study: Industrial Manufacturer in Johor

A leading plastic parts manufacturer in Johor replaced their legacy heating chambers with two high-efficient heating chambers supplied by ISSES Malaysia. Results after 12 months:

- Energy consumption reduced by 28%

- TNB bills cut by RM 62,000 annually

- Product rejection rate dropped by 15%

- ROI achieved in 2.3 years

This success story highlights the measurable impact a well-designed heating system can have on operational performance and cost efficiency.

Future Trends: The Evolution of Heating Chambers

The high-efficient heating chamber is already a futuristic solution, but technology continues to evolve. Here’s what’s next:

● AI-Powered Heating

Artificial Intelligence will enable real-time optimisation of temperature curves, reducing errors and improving product quality.

● Renewable Energy Integration

Heating systems powered by solar PV or biomass will further reduce emissions and reliance on grid electricity.

● Modular and Scalable Designs

Smaller, stackable heating units can be configured based on production needs, improving flexibility and space utilisation.

● Carbon Emission Reporting Tools

Built-in tools will allow companies to calculate and report on emissions per batch, aiding ESG compliance and transparency.

Conclusion: Power Your Process with a High-Efficient Heating Chamber

In a rapidly evolving industrial landscape, investing in a high-efficient heating chamber is not just a smart move — it’s a necessary one. With increasing energy costs, stricter environmental regulations, and the push toward Industry 4.0, the demand for efficient, precise, and intelligent heating systems is higher than ever.

By upgrading your operations with ISSES Malaysia’s high-efficient heating chambers, you gain a competitive edge in efficiency, sustainability, and reliability.

Ready to transform your thermal processing?

Contact ISSES Malaysia today for a consultation and let us help you find the right heating solution tailored to your industrial needs.

Recent Comments